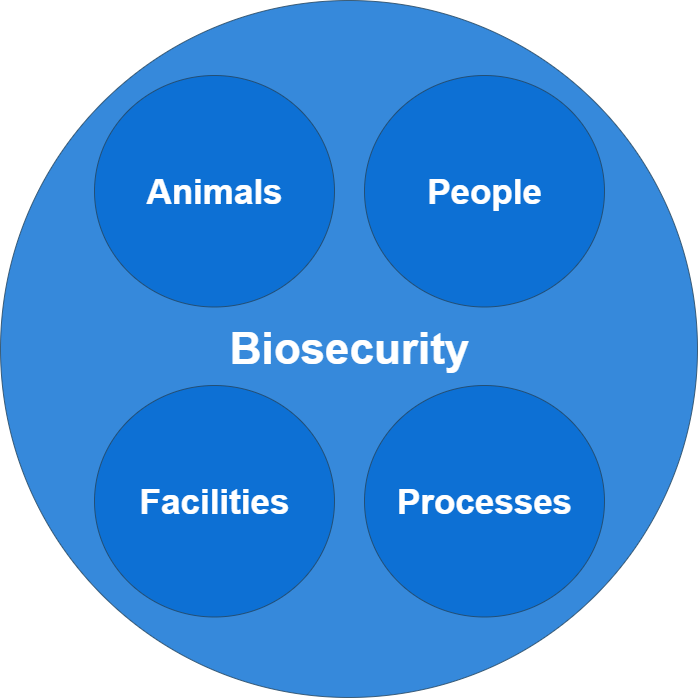

8.0 Biosecurity for Aquatic Livestock Production

8.6 Processes

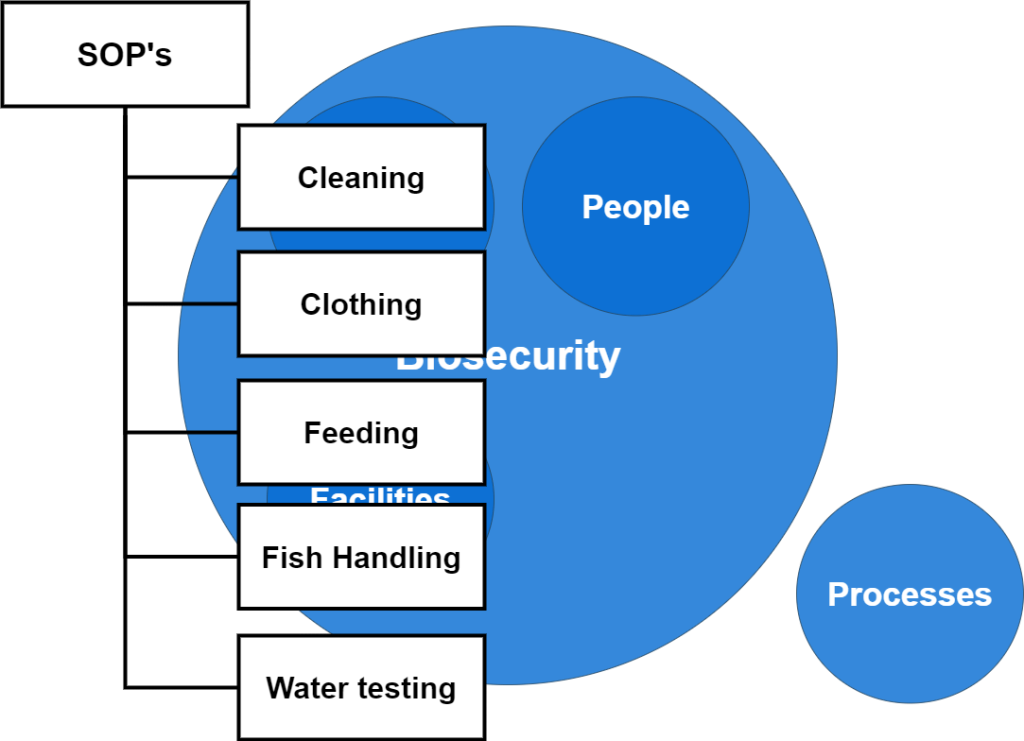

The final factor in this discussion system of biosecurity is processed. The steps or flow of actions to create the desired result are described in the SOPs. Processes that are significant to the facility’s operation are stated in SOPs. These documents do not have to be elaborate or detailed for some processes. , they define the job, the person responsible, how the job is done in steps, the expected outcome, and the records to be completed.

The image below is a short list, but the entire list depends on the facility. An extensive production facility (outdoor ponds and raceways) will have SOPs for cleaning and disinfecting seines and other netting equipment; cleaning and disinfecting boats, trucks, and tanks; as well as loading/unloading protocols.

A simple, effective net disinfection for an outdoor facility is drying in strong sunlight on a mowed lawn without foot or vehicle traffic. The sunshine net protocol is not used in cooler months. The sunny summer days are best for this process. Rainy days will not provide effective disinfection. The best plan is to hang the seine-netting off the ground or floor after disinfection for better drying as a routine process on sunny, cloudy, or cold days. The cleaned nets will be hung over overstretched lines for drying and storing off the floor.

Successful biosecurity plan implementation will have its unique composition. Some visible traits include cleanliness, organization, and visible purpose for the equipment, personnel, and activities. Personnel need to be trained and have adequate numbers to conduct the “chores” needed in tending the needs of these animals.

Why Is Biosecurity Important?

Remember that infectious diseases and parasites are the main cause of business failures in aquatic livestock production. Millions of dollars can be invested in facilities without ever seeing a profit and, on some occasions losing the entire investment and still being in debt. In the Mississippi Delta, amongst the catfish farmers, the popular saying “to make a small fortune raising fish, it takes a large fortune to start” applies to catfish and all aquaculture investments. The learning curve is extremely steep for the novice. NEVER assume that commercial-scale aquatic livestock production is similar to aquariums and Koi ponds.

BPs should not be too complex to follow. Complicated or complex BP’s lack focus on the practical steps needed to keep livestock healthy.

Documentation

Finally, the BP will require documentation and archiving to verify that the work was attended to. An old phrase from author’s experience in investigation states, “If it was not written down, it did not happen.” The records should be simplified as much as possible. A simple audit will see how different records can support each other. The cross-purpose and filing will be especially useful IF a foreign animal disease erupts. Record keeping may keep the farm from depopulating and starting over.

An example of a record system used on an extensive culture farm rearing ten species and selling to a dozen or more states involves dual purpose records such as the sales receipt. The receipt at the point-of-sale records the owner’s name, address, and phone number, along with the species list, number, size, and location. This receipt could shorten the time spent tracing and figuring out where a pathogen has been distributed on the farm and amongst customers. Daily mortality records would overlap with locations being stocked for sale and loading.

This simple record set would account for the fish and clinical condition to cover the typical incubation period of many infectious diseases. Adding a record of animal movement from rearing ponds into the load-out locations would allow tracing to the on-farm source of infection. The rearing pond records would record when they were stocked with fry and how many. When the farm has several hundred surface acres of water divided amongst dozens of impoundments, it takes records to backtrack what has happened.

Next is an exercise to identify what category of the BP is being discussed and needs correction. Can the following pictures of facility scenarios be properly classified into one of the four groups of biosecurity concerns?