12.0 Biosecurity for Aquatic Livestock Production

12.4 People

Simply put, PEOPLE DO NOT BELONG IN THE PRODUCTION AREA of intensive-production systems. Extensive culture systems (i.e., outdoor facilities) may not need the level of biosecurity generally discussed in this chapter. However, the outline taken from this discussion will be a decent guide for outdoor facilities. Visitors will not be provided access to ponds, e.g., for sport fishing. Trained designated employees will operate the production area according to protocols meant to avoid disease introduction and spread. The production area in this discussion is the interface of human-animal interaction. This interaction may be observed at the tank side, feeding and taking livestock samples for laboratory assays. A distinction is needed between production area activities and support activities. Strive for support activities (e.g., water testing and adjusting water flows) to be delegated to a separate space in the facility. You may wish to return to the Facilities discussion in the previous section to identify rooms that can house support activities outside the production area.

Automation and cameras can eliminate some of the tasks that require human interaction. Automatic feeding is an example, and moveable cameras can check on tanks around the facility. Mounted underwater cameras can be furnished for observation that would have required human entry into the water. Remote sensing allows meters or gauges to be read outside the production area, perhaps in the laboratory with alarms and viewing windows for production employees to check conditions without leaving the production area.

Today, automated facilities are being built that can be monitored in real-time in other countries. Such is the oversight on risk avoidance in multimillion-dollar projects.

Employee Access

People are a significant risk that should be addressed in a successful BP and relevant standard operating procedures (SOPs). Well-trained employees are a huge asset to have working under an adequate BP. In a risk-assessment sense, “people” do not have the same working definition as “employees.” This working definition is especially poignant in distinguishing between production and administrative or management employees.

Tragically, managers and owners do not often understand being restricted from the livestock areas of their investments. Financial obligations do not provide the privilege to enter the production area. Required training does provide the basis for entrance. It is noted in this author’s experience that larger facilities may seek bragging rights to potential investors by giving production area tours. Hopefully, any investors reading this chapter will realize the risk of bringing untrained citizens to walk through a facility.

Anyone putting bare hands in water, handling a net handle with bare hands, or cupping pelleted feed in open uncovered hands could potentially inoculate the system with pathogens. If untrained management and visitors cannot perform activities except to walk through the production area, a mezzanine or observation windows would be more appropriate at much less risk.

It may be sufficient to provide viewing monitors from cameras in the tank’s interior to an exterior visiting area, incorporating several biosecure avenues into the facility design.

Alternatively, a separate “public” tank could be made accessible to investors and visitors as an educational tank at a reduced scale to the actual production tanks. Education of the investors will also maintain a clear line of demarcation between the massive biosecure production sites and fish to be scrutinized by investors.

External Personnel Access

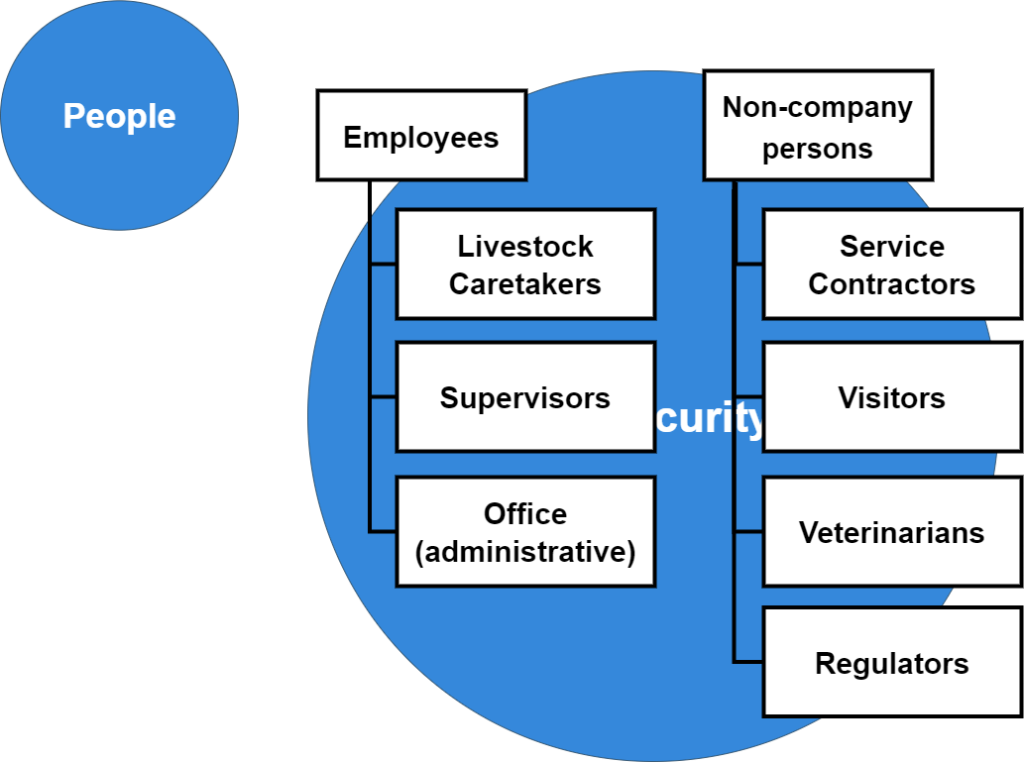

Some outside personnel will need access to production areas when needed for equipment repairs or disease treatments. In designing biosecure facilities, many levels or systems installation must be considered. Electrical connections can be placed in electrical rooms with access from outside the production areas. Meters for monitoring and switches to control processes can be mounted in panels outside walls with maintenance and repair access from outside. Water pumps can be plumbed from a separate plumbing room. Engineers, plumbers, and other service personnel do not have to enter the production area when pumps need replacement. In Image 12.07, the people category of employees is shown as either “employees” or “non-company persons.” The employee roster may include mechanical and veterinary personnel on the payroll at large operations. In most smaller facilities, some specialized tradespeople will be called in to do expert work. Therefore, the distinction will be used to assure adequate training, assistance, and supervision.

Additional Examples

Employees listed as “livestock caretakers” are trained to work in the production area with the livestock. These employees have been trained to conduct their work without contaminating or spreading pathogens to livestock.

When properly trained in biosecurity processes, supervisors can be useful in production areas but otherwise should avoid entering the area. It can be tempting for those who make temporary or quick visits to circumvent shower-in-shower-out systems. Instead, alternatives to entering the production area should be available and easily accessible to supervisors. In-house phones or message windows can replace the need for supervisors to relay messages in person within the facility. Cell phones can be kept in waterproof cases that can survive washing and disinfecting. These devices are additionally useful for photographing clinical signs and other problems needing supervisor attention.

Veterinarians are essential persons to animal health. However, attending veterinarians can also become fomites of pathogens if adequate biosecurity precautions are not provided and followed. Not every veterinary visit requires tank-side attendance. If the risk of disease spread prevents the attending veterinarian from direct observation, utilizing cell phones, concurrent animal observation, and sampling observation can be done at a distance while maintaining the standard of care.

Emergency exits are intended for evacuations or direct access by emergency personnel. Production area employees must not be permitted to exit or enter via emergency exits, except in emergencies. One method of preventing unauthorized emergency exit use might be to equip emergency doors with an alarm that sounds when the door is used. These alarms effectively discourage caretakers from abusing emergency doors. The emergency exits must never be locked to prevent employee passage. The production area employees need to follow standard protocols for entering and leaving the production area. Supervisors are not emergency responders and should not be permitted to enter or exit through emergency exits. Supervisors may be usefully trained in biosecurity when they fill in for absent caregivers and should enter and exit through the biosecure access points. The scenario shown in 12.08 shows when biosecurity is adequate in the People category.

Finally, regulators may need entry into production areas from time to time. Regulator entry may be necessary for certifying weighing scales or employee safety programs. To date, aquatic livestock has numerous commercial certification programs. These non-employees will need to have suitable training and attire to reduce the risk of contamination.