Chapter 7: Launching Improved Cultivars

Rita H. Mumm

Preparing For New Product Release

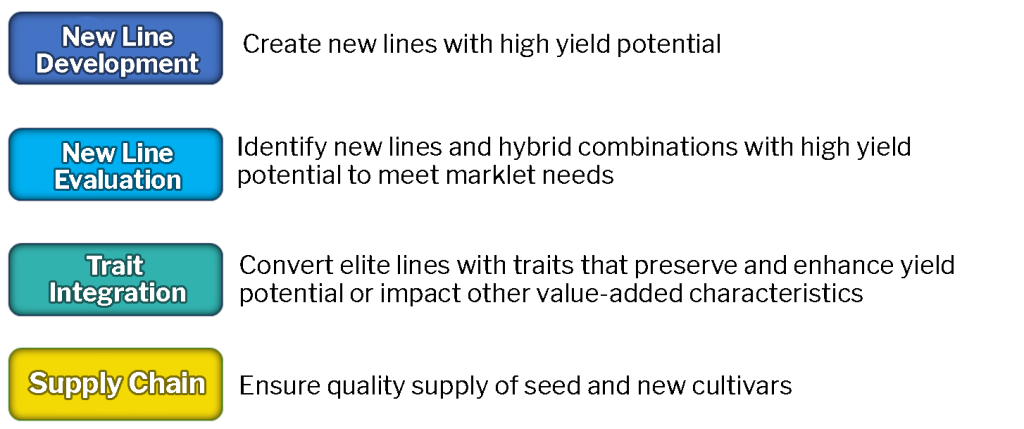

Once a superior line meeting the product target is identified, and it is determined that the potential new cultivar can be reliably reproduced, steps toward product release are set in motion. The preparations for launching a new cultivar are largely a function of the Supply Chain, which is the final stage of the process of cultivar development (Fig. 1).

Variety Registration and Varietal Performance Testing

The new cultivar must represent a new genetic entity (not previously commercialized); it must be distinguishable from other varieties. In many countries, variety registration testing, often referred to as DUS, is conducted to establish the identity of the new cultivar based on four aspects:

- Distinctiveness from other existing varieties.

- Uniformity such that individual plants reflect consistency in quality and in the level of variation within the population.

- Stability of distinctive characteristics manifests through generations of propagation.

- Varietal Identity in terms of defining morphological characteristics.

In DUS testing, the performance of the potential new cultivar is compared to a wide range of existing varieties to validate its unique benefits and attributes. A detailed description of DUS testing guidelines and procedures is available from the International Union for the Protection of New Varieties of Plants (UPOV).

In addition, Varietal Performance Testing, often referred to as VCU, is conducted to demonstrate the merit of the new cultivar to stakeholders in the value chain, i.e., producers, end-users, and consumers. Typically, the test results must prove the new cultivar is superior to existing varieties in one or more aspects, e.g., yield, disease resistance, and nutritional value. VCU is typically conducted through on-farm trials for multiple years.

The new cultivars that meet requirements for registration and performance through DUS and VCU testing are officially approved for commercialization and are listed in a variety register. Note that requirements vary from country to country. DUS and VCU requirements need to be accommodated in the design of the testing regime for cultivar development.

Priorities in Scale-up to Commercial Quantities

To launch the new cultivar, that is, release it for commercial distribution, it is critical to maintain genetic integrity, and purity, and to keep the propagation materials free from pests and diseases as the scale-up to commercial quantities is performed.

Critical issues differ depending on whether the new cultivar is seed-propagated or vegetatively propagated.

Clean Stock of Clonally-propagated Cultivars

To generate a “clean” stock of a clonally-propagated cultivar, a heat treatment may be applied ahead of isolating meristematic tissue for culturing to kill off any pathogens. Clean plant stock source materials can be stored long-term through cryopreservation (Fig. 2).

To maintain and increase clean stock, best practices include:

- Physical isolation, i.e., planting distance from potential sources of infection.

- Control of insect vectors of disease through the use of screen houses or cages, chemical controls, or distance/time isolation.

- Inspection and testing, e.g., visual observation, use of indicator plants/grafting, and/or diagnostics such as ELISA assays or molecular marker analysis to monitor for pathogen presence.

Producing Commercial Volumes of Seed-propagated Cultivars

For new cultivars propagated by seed, seed quality is a key priority at every stage in seed production and scale-up (Fig. 3).

Seed quality reflects a number of parameters to ensure genetic integrity and purity, seed vigor, the absence of pathogens, and cleanliness. Because producing commercial volumes of the new cultivar is a multi-step process, seed quality must be safeguarded through each step to achieve the desired result for distribution to farmers.

Seed Classes From Breeder’s Seed to Commercialization

It all starts with breeder’s seed, which is produced in the initiating breeding program through controlled hand pollination. Breeder’s seed represents the standard of genetic identity to which all other increases of the line will be compared. Breeder’s seed is provided to Supply Chain through a hand-off from the plant breeder who developed the new cultivar. The development and maintenance of breeder seed is an important obligation of the plant breeder.

The breeder’s seed is used by the Foundation group to increase the variety or parent line, producing pre-basic and foundation seed. In the case of a hybrid cultivar, Hybrid Seed Production follows to create the hybrid seed that will be sold to farmers/growers and, in the case of 3-way or double-cross hybrid cultivars, any intermediary hybrid materials. See Chapter 3 for more on the types of hybrids and requirements for utilizing hybridization in crop improvement (e.g., male sterility systems).

Certified seed production is governed by the national seed regulations of the country in which the seed is to be produced, with the aim to produce seed for commercial distribution that meets standards for genetic purity, seed germination, seed moisture, and the presence of premium value-added traits. Internationally recognized, the Organization for Economic Co-operation and Development (OECD) provides guidelines for seed certification (Table 1). (Note that certified seed is not required for commercial distribution by every country for every crop.)

| Seed Class | Produced from | Comprised of |

|---|---|---|

| Pre-basic seed | Breeder seed | Cultivar per se -or- parent line of hybrid cultivar |

| Foundation seed (or Basic seed) | Pre-basic or breeder’s seed | Cultivar per se -or- parent line of hybrid cultivar |

| Registered seed | Foundation seed | Progeny of foundation seed or registered seed used to produce certified seed |

| Hybrid seed | Crosses between parent lines increased by Foundation seed group | Hybrid cultivar -or- intermediary hybrid in the case of 3- or 4-way hybrid cultivars |

| Certified seed | Foundation or higher seed classes | Cultivar per se including hybrid cultivar |

See “Molecular Plant Breeding, Chapter 12. Genomic Tools for Variety Registration and Protection“, for more detail regarding rules for certified seed production.

Best Practices in Seed Production

With the goal to produce quality seed for cultivar release, steps to safeguard genetic purity are implemented at each stage of seed production. Logistics are arranged to ensure the designated pollen and seed parents are involved and to maximize seed returns.

Safeguards include:

- Proper isolation of production fields to minimize the chance of stray pollen. The physical isolation distance per crop depends on pollen mobility. For maize, an isolation distance of at least 300 meters is typically employed. Fields can also be isolated in time; other fields in close proximity are arranged so that pollen shed is not occurring at the time when production fields are receptive to pollen. Furthermore, other fields in proximity to the seed production field are monitored throughout the season to check for risks of pollen migration.

- Field selection to facilitate control of soil-borne disease (no previous history) and absence of volunteer plants (of the same species).

- Ideal agronomic management (e.g., fertility, planting, disease control, soil moisture, etc.) to facilitate top yields.

- Careful cleaning of planting and harvest equipment (e.g., planters, combines, threshers, trucks, bins, etc.) to ensure no seed carryover and prevent inadvertent contamination through seed mixing.

- Judicious placement of insect pollinators (as needed depending on the crop) to facilitate pollination.

- Field inspection throughout the growing season.

- Careful record keeping to maintain chain of custody documentation from seed source through each seed increase to final production.

- Accurate labeling of harvested seed to safeguard genetic authenticity.

Additional Best Practices For Production of Hybrid Seed

In hybrid production, care is taken in the placement of the female parent plants to the male parent plants to ensure ample movement of pollen from male rows to female rows. In addition, the ratio of male rows to female rows is designed to facilitate sufficient pollination. Corn hybrid production typically features a 2:1 ratio as seen in the photo (Fig. 4); four rows of female inbred flanked by two rows of male inbred.

With some crops such as rice, movement of the relatively heavy pollen grain is aided by mechanical means. For example, a helicopter flown overhead at peak pollen shed will move pollen by wind to female plants.

It is critical that male and female parent plants are flowering simultaneously. This is referred to as “nicking.” Sometimes to achieve the nick, one parent is planted later than the other in keeping with known maturity of the lines. With some crops, the earlier female or male parent may be “trimmed” to trigger a second flowering.

Generally, male rows in a hybrid production field are harvested or removed from the field ahead of harvesting of the female rows to prevent contamination of the hybrid seed (with selfed seed of the male parent).

Foundation Research

Once the hand-off of breeder seed to supply chain occurs, it is the responsibility of the Foundation seed group to maintain the genetic integrity of the variety or parent seed. With seed increases, measures are taken to prevent genetic drift, contamination through pollen migration, and unintended seed mixing, and to ensure accurate seed labeling (as described previously).

In addition, the Foundation seed group often includes a research arm to optimize seed multiplication and hybrid production. Each line it maintains is characterized in depth and, for hybrid cultivars, parent lines are assessed to facilitate best practices to achieve optimal seed quality and output in hybrid production in a cost-effective manner.

Seed Quality Tests

Once harvested, each lot of seed of the new cultivar undergoes screening and testing to determine seed quality and purity.

Evaluations may include:

- The ratio of seed to other materials such as weed seed and inert matter.

- Genetic authenticity to ensure proper labeling.

- Seed purity and percentage of off-types.

- Rate of germination as a measurement of seed vigor.

- Seed moisture content to indicate whether further drying of the seed is required to prolong shelf life.

- Freedom from adventitious presence of GM events.

- Freedom from disease and pests.

Genetic Authenticity and Seed Purity

Genetic authenticity (and seed purity) may be verified through DNA fingerprinting to ensure the genetic makeup of the seed matches that of the intended cultivar. This DNA fingerprint also represents a genetic profile to support intellectual property protection of the new cultivar. See “Molecular Plant Breeding, Chapter 12. Genomic Tools for Variety Registration and Protection” for details on establishing the DNA profile for varietal registration as well as protection of new cultivars.

To monitor seed purity, a “grow out” of each seed lot is typically performed to check for characteristic morphological properties, absence of off-types, and percentage of seed exhibiting any premium value-added traits (e.g., herbicide tolerance, oil profile). In this way, the genetic purity of the given seed lot can be determined as well as the extent to which the seed lot sample conforms to the prescribed standard.

For the grow-out, the size of the sample representing a given seed lot depends on the predetermined threshold for off-types. For example, if no more than 1 percent off-types are allowed, at least 400 seeds (i.e., plants) must be tested. For stricter standards, larger sample sizes are required (Table 2).

| Threshold for off-types (%) | Minimum level of genetic purity | Sample size per seed lot |

|---|---|---|

| 0.01 | 99.9 | 4000 |

| 0.20 | 99.8 | 2000 |

| 0.30 | 99.7 | 1350 |

| 0.50 | 99.5 | 800 |

| 1.00 | 99.0 | 400 |

The grow-out should be conducted in the target market region in a field free from potential volunteer plants. Furthermore, the grow-out must be managed in keeping with agronomic practices recommended to farmers for production of the new cultivar including planting date, plant spacing, fertilization regime, and other cultural practices.

The percentage of off-types is estimated for each seed lot from the results of the grow out and the number of seeds (i.e., plants) in the sample which do not conform to the prescribed standard.

Seed Germination Testing

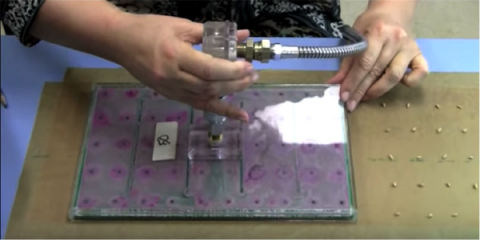

To determine the germination rate of a seed lot, a sample of seed from each seed lot is collected, cleaned, and germinated on a moist substrate under laboratory conditions, with replication. The mean percentage of seeds that germinate to produce normal seedlings can then be estimated for that seed lot (Fig. 5).

Phytosanitary Testing

Seed lots must be checked for the presence of seed-borne disease and insect pests and disease-carrying organisms (Fig. 6). Such tests serve as a backup to field scouting during seed increase and hybrid production.

Testing for Adventitious Presence of GM Events

Just as seed lots are evaluated for the percentage of plants expressing premium value-added traits, seed may also evaluated for the absence of other traits, particularly those resulting from genetically modified (GM) events, that are not intended as part of the genetic package of the cultivar.

Because traits created through genetic modification (e.g., GM events) are subject to regulation on a country-by-country basis, seed must be tested before product release to ensure that only desired GM events, consistent with seed labeling, are present. This type of testing, which evaluates for adventitious presence, is conducted through DNA analysis, using markers for the DNA sequence characteristic of known events.

See “Molecular Plant Breeding, Chapter 12. Genomic Tools for Variety Registration and Protection” for more detail on monitoring for absence or presence of transgenes.

Overview of Production of a Given Seed Lot

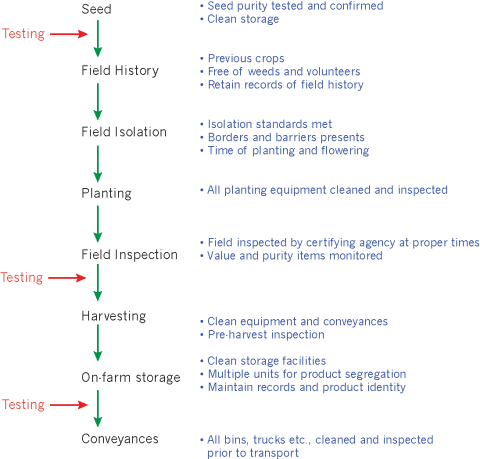

In summary, an effective seed production process utilizes best practices and features points at which monitoring is conducted to verify seed integrity, purity, and quality. The graphic below (Fig. 7) depicts examples of test points that might be implemented in a seed increase or hybrid seed production.

Packaging Seed for Distribution

Seed lots that pass the strict standards for various tests are stored under conditions conducive to long seed life, controlling moisture/temperature levels.

To prepare seed for distribution of the new cultivar:

- seed is cleaned to remove any weed seed or inert matter.

- seed treatments may be applied as desired (e.g., seed-applied fungicides or microbials to stimulate seedling growth).

- seed is packaged to prevent absorption of water from the atmosphere and to keep seed contained and inaccessible to insects and disease.

- seed bags/containers are labeled.

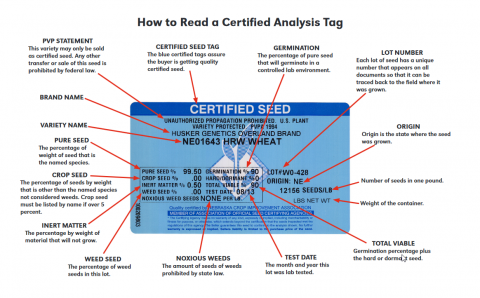

The seed container must be accurately labeled (or “tagged”) (Fig. 8), listing information related to the specific variety, the seed lot and origin, seed testing results of the seed lot, seed purity, etc. Varieties featuring value-added traits typically list the thresholds of seed purity for these traits. With certified seed, tags reveal these important details and more.

Promoting the New Cultivar

The breeder has a role in creating awareness and demand for the new cultivar. He/she may set up demonstration plots to highlight soon-to-be-released varieties or new value-added traits to farmers (Fig. 9). Field days at the research station represent a good opportunity for breeders to exhibit characteristics of new varieties or traits to farmers and growers.

Furthermore, the breeder can make recommendations as to appropriate agronomic practices to maximize and protect yields, which are critical to farmers’ success, especially with new cultivars.

The goal is to promote rapid adoption of new, improved cultivars.

Protecting Intellectual Property

The new, improved cultivar represents an important investment of skills, time, energy, and resources. To recoup the investment and to provide the incentive for further development of improved varieties that meet stakeholder needs, the intellectual property represented by the new cultivar must be protected.

A number of mechanisms are available to protect the interests of plant breeders and foster the development of a robust national seed sector, including:

- Plant Variety Protection (PVP) for seed and tubers.

- Plant patents for asexually propagated plants, except tubers.

- Utility patents for any type of plant showing a particular utility or purpose.

- Contracts.

- Trade secrets.

Plant Variety Protection (PVP)

A key mechanism recognized worldwide is Plant Variety Protection (PVP), which provides intellectual property protection for unique varieties of a sexually-reproduced plant or tuber-propagated plant for 20 years (25 years for trees and vines).

PVP is governed by the International Union for the Protection of New Varieties of Plants (UPOV), which was established in 1961 as an outcome of the International Convention for the Protection of New Varieties of Plants. The mission of UPOV is to provide and promote an effective system of plant variety protection, which encourages the development of new, improved varieties of plants for the benefit of society. PVP provides the basis for plant breeders’ rights to intellectual property pertaining to their innovation.

To apply for PVP protection, the breeder of the new cultivar (or his/her employer) must file an application with the authorities of UPOV. The African Intellectual Property Organization operates a plant breeders’ rights system which covers the territory of 17 member states. Applications can be filed with authorities entrusted with the responsibility of granting breeders’ rights.

PVP Provisions

PVP is not intended to restrict farmers from saving seed for their own purposes, nor does it restrict private use of the variety for non-commercial or experimental purposes. PVP does allow the use of the protected variety in breeding to develop other improved cultivars, provided the new cultivar is not essentially derived from the protected cultivar. Thus, the protected variety can still contribute to the advancement of improved varieties during the 20 years of coverage; PVP does not slow innovation.

PVP does guard against marketing and selling of the protected variety, or a variety essentially derived from the protected variety, by other commercial entities. PVP also forbids multiplication of the protected variety or import/export without the express authorization of the breeder.

However, enforcement of the PVP falls to the breeder and his/her organization. As a basis for such enforcement, a DNA fingerprint of the protected variety produced in accord with established standards of protection in the crop species can be used to expose the genetic identity of suspected offenders.

Once the term of PVP protection has expired, the variety is considered “public domain.” Thus, the net result is to encourage more innovation, which ultimately promotes food security and benefits the consumer.

Sharing Germplasm

Plant breeders are advised to keep good records of germplasm in inventory as well as germplasm shared with others. Such records will be important in protecting intellectual property embodied by new cultivars.

A Standard Material Transfer Agreement (SMTA) is a contract between the provider and the recipient of the germplasm. Basically, the provider agrees to share the germplasm and other available non-confidential descriptive information about the plant materials. The recipient agrees to use the materials for research, breeding, or agricultural training, without claim to intellectual property. Should the recipient commercialize a product that incorporates or is developed from the material, the SMTA outlines expectations for compensation, if any, to the provider.

See Crop Improvement: Genetic Variation and Germplasm Usage for more detail on SMTAs.

Starting the Cycle Anew

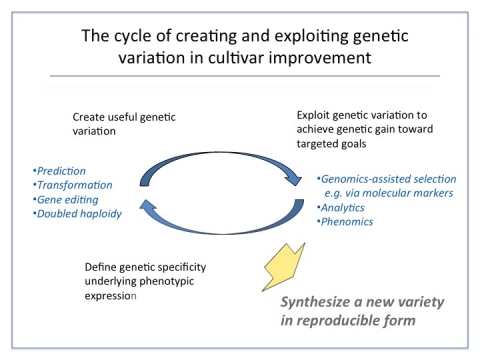

This course in Cultivar Development has focused on the cycle of cultivar improvement and design of the process pipeline to effectively facilitate the efficient development of improved crop cultivars.

The launch of a new, improved cultivar that meets the needs of stakeholders embodied in the product target represents the close of one cycle and triggers the start of another. A plant breeder’s job never ends!

Now, with the start of a new cycle, product targets are redefined or adjusted in keeping with reassessment of stakeholder needs and desires. Armed with the information gleaned from past cycles, the breeder is better informed with respect to genetic architecture of traits of interest and how such traits interact with the environment, and each other, and is better able to choose parents to create new breeding populations, identify or create effective testing environments, and employ technologies (Fig. 10). Thus, knowledge gleaned can lead to better ways to create useful genetic variation and more effective ways to exploit this variation to achieve stated product targets.

What types of information acquired during the development of an improved cultivar might serve to better guide choice of parents and to enhance evaluation/selection of progeny in future cycles?

References

Baenziger, P.S., R.H. Mumm, R. Bernardo, E.C. Brummer, P. Langridge, P. Simon, and S. Smith. 2017. Plant Breeding and Genetics—A paper in the series on “The Need for Agricultural Innovation to Sustainably Feed the World by 2050.” Council for Agricultural Science and Technology (CAST), Issue Paper 57, Ames, Iowa.

Bishaw, Z., and A.J.G. van Gastel. 2009. Variety release and policy options. In S. Ceccarelli, E.P. Guimaraes, E. Weltizien (eds), Plant Breeding and Farmer Participation. Food and Agriculture Organization of the United Nations (FAO), Rome. FAO

MacRobert, J.F., P.S. Setimela, J. Gethi, and M.W. Regasa. 2014. Maize Hybrid Seed Production Manual. Mexico, D.F.: CIMMYT.

Mumm, R.H. 2013. A look at seed product development with genetically modified crops: Examples from maize. J. Agricultural and Food Chemistry 61(35): 8254-8259. DOI 10.1021/jf400685y

Mumm, R.H., and D.S. Walters. 2001. Quality control in the development of transgenic crop seed products. Crop Sci. 41:1381‑1389.

Sundstrom, F.J., J. Williams, A. Van Deynze, and K.J. Bradford. 2002. Identity preservation of agricultural commodities. University of California, Agricultural Biotechnology in California Series, ANR Publication No. 8077. ANR Catalog, UC-Davis

USDA ARS National Laboratory for Genetic Resources Preservation. Clonal Brochure No. 11182016. USDA-ARS.

Xu, Y. 2010. Intellectual property rights and plant variety protection. pp 512-549. In Molecular Plant Breeding. CAB International, Cambridge, MA.

How to cite this chapter: Mumm, R.H. (2023). Launching Improved Cultivars. In W. P. Suza, & K. R. Lamkey (Eds.), Cultivar Development. Iowa State University Digital Press.

Class of seed representing the standard for a given variety or parent line.

Represents the simultaneous flowering of male and female parent plants (or plant parts) that will result in successful pollination.

A batch of seed produced in the same production field from the same seed source.

Creation of a DNA profile characterizing a particular line or variety, which is obtained through measurement with a specific standard set of molecular markers.

Sample of each seed lot which is grown for evaluation throughout the plant life cycle for conformity to morphological and chemical characteristics consistent with a specific genetic entity.

Unwanted presence of certain genetic elements, especially those created through genetic engineering.

An essentially derived variety is predominantly derived from another variety (“initial variety”) and conforms to the initial variety in the expression of the essential characteristics of the initial variety. An essentially derived variety may be obtained through methods such as backcrossing, transformation, and mutagenesis.