1 Introduction to Food Product Development

To start, let’s think about what product development is:

- How new things show up in the grocery store or in foodservice

- The process of creating, processing, and commercializing a new food product

- The process generally takes a group of people from different disciplines working together to develop (or improve) a product.

Product Development Key Stages

- Ideation

- Formulation

- Processing

- Commercialization

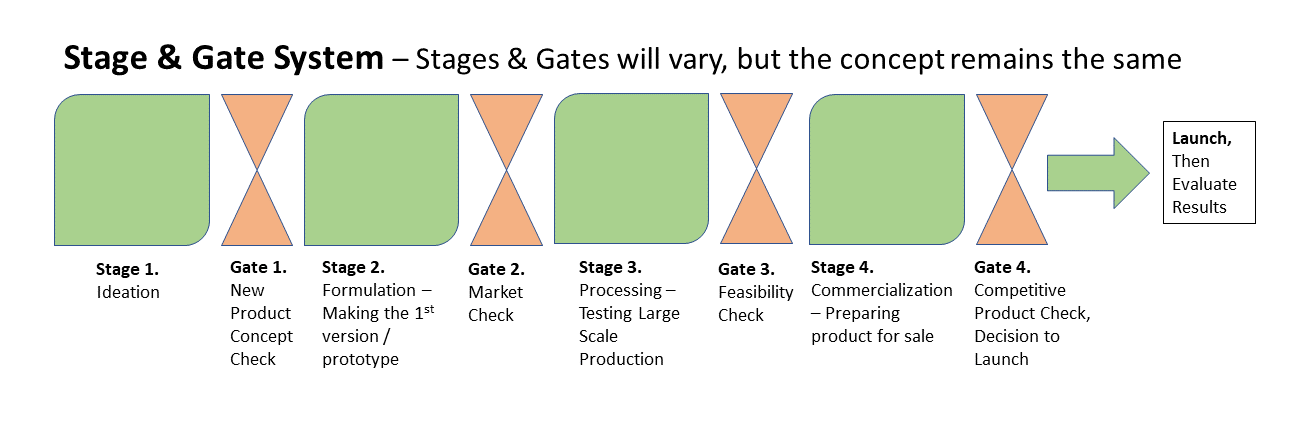

At each stage, or even within the stages, there are checkpoints to decide to continue or stop the project. This can be done through a Stage and Gate System like the example shown here or it can be done in a modified system. The principle is the same, though, to develop new products strategically and use time and resources wisely.

Typically this Stage and Gate process works like a funnel. You may start with 12 to 15 ideas and then research and evaluate those ideas. Some ideas will get discarded because you will find the product concept already exists. Others will get discarded because the ingredients or processing will cost more than what consumers are willing to pay (based on products in the relevant category). Some ideas will seem great, but will be too niche and will not have a large enough target audience to be successful. Once the ideas have been narrowed down, the best 3 to 5 ideas may be moved to the Formulation stage. In this stage, the product will be made on a small scale and consumer testing will be done to confirm interest. Then products will go through the second gate to determine which products have enough consumer interest to continue. During the Processing stage, 2 to 3 products are scaled up on larger equipment. This helps determine production costs and efficiency. Food safety and quality testing also are done to determine how to produce a safe and consistent product. Shelf-life testing is conducted at the end of the Processing stage to make sure the product will remain at an acceptable and safe quality long enough for the product to made, shipped, purchased, and consumed. The third gate evaluates production, food safety, quality, and shelf life to decide which products can actually be made efficiently and consistently. The Commercialization stage includes work to get the product ready to sell on the grocery store shelves. Typically this includes the final costing, additional consumer sensory testing, and package design. The final gate makes sure that no errors or significant drawbacks have been missed before the product is launched. Through the Stage and Gate process, 12 to 15 ideas may get narrowed down to 1 or 2 products. The Stage and Gate process allows many ideas to be considered efficiently. The more viable the idea, the more time and work is needed. When an obstacle is found at a gate, no more time or resources are committed to that idea.

Each company may work through the stages of product development a bit differently depending on resources, timelines, and product types being developed. In a product development course, a product is likely developed from start to finish, so more market, consumer, and product research will need to be done during the ideation stage to catch significant drawbacks.

Ideation

Often the most difficult part of product development is coming up with the initial idea. Many food products exist in the marketplace, so coming up with a new food product that does not exist and consumers are interested in buying can be a challenge. It is best to simply jump in and start generating ideas. From there, concepts can be refined and narrowed down. Ideas can come from a variety of sources. Some ideas are for a brand-new product and some are for a line extension of an existing product. Once ideas have been generated, it is important to identify the target customer. Trends are followed closely to determine what is new and upcoming. Trends often spark ideas for new products. Trends change over time, so it is difficult to list current examples, but convenience products, comfort foods, and plant-based foods have been trending over the last few years.

Some issues with ideation include regional vs. global preferences and market size vs. target market. Flavors that are commonly known and liked in the Midwest may not sell well in other parts of the country. Consumers outside of the Midwest may not like those flavors or may simply be unfamiliar with the flavors. If your target market is a small part of a product category and the product category itself is small, there may not be a large enough market share for your product. It also can be a challenge to realize that just because you like something, many others may not. We tend to develop products we like, but sometimes you may have to develop a product for a target audience that does not include you.

Formulation

- Making the new product!

- Procure ingredients and make them into a product on a small laboratory scale

- Produce a “gold standard” of the new product

- Possible issues

- Sourcing ingredients and ingredient costs

- Product shelf life (often not tested in formulation, but needs to be considered early in the process)

- Can the product really be made on a large scale?

- Avoid Patent and Copyright infringement

Processing

- The formulated product process is “scaled up” to produce greater volumes

- Often the process is “scaled up” more than once.

- Pilot plant testing

- Plant testing

- There are always product changes with scale-up.

- Quality & Proximate Analysis testing done to set specifications, determine food safety concerns, and estimate shelf life

- Processing experiments and runs allow a more accurate product cost to be determined (include processing efficiency, rework used, etc.).

Processing Key Questions:

- What effect will the process have on the product attributes

- Sensory Attributes

- Nutritional Profile

- Product Specifications

- Shelf Life

- Overall Functionality

Commercialization

- Once the new product has been made successfully, it is sent to commercialization to launch the new product into the store for sale.

- Steps include:

- determining packaging

- creating a label (logo, nutrition facts, etc.)

- finalizing costs

- developing advertising and/or literature for the product

Commercialization Key Questions:

- How should the product be positioned for the best sales?

- What attributes do you highlight?

- Where does it go in the grocery store (should consider this throughout the development process)?

- What effect will the distribution system have on product quality?

After the launch of a new product:

- Determine if the new product was successful.

- Success can be measured by:

- Growing interest, increase in sales

- Market share

- Company sales revenue

Key Team Members

It takes many roles to develop a new food product. A product development team can be very successful with all members contributing an expertise. The challenge is communicating effectively to make sure everyone is on the same page with the status and goals of the project. Key team members include product development, engineering, production, purchasing, quality, regulatory, marketing, sales, and upper management. Their typical roles are laid out below.

Product Developers

- In charge of developing new products, especially in terms of the hands-on testing and managing the development process

- May be the Team Leader

- Duties:

- Formulate Product

- Determine Sensory Attributes

- Run Shelf Life Testing

- Know Food Safety Concerns

- Test the Process

- Consider Nutrition

- Calculate Costs (may need input from others)

Engineering and Production

- Engineers & Production Managers help determine Process Design:

- Equipment Design and Maintenance

- Process Controls

- Production Costs (line speeds, overhead cost)

- Employee Training

- Sanitation

- They may also help with Package Design

- Shelf Life

- Handling

- Cost

- Consumer Safety

- Consumer Handling

Quality

- Ensures consumer expectations are met

- Sensory and Quality attributes are tested to make sure the product meets specifications

- Food Safety

- HACCP and Preventative Controls plus Prerequisite Programs

- Microbiology Testing

- Foreign Material Testing

- Process Checks

- Incoming ingredient and packaging safety checks

Regulatory

- Makes sure the new product is legal and safe

- Coordinates a Generally Recognized As Safe (GRAS) dossier if necessary (typically for ingredient development)

- Regulations

- Product Name

- Standard of Identity

- Nutrition Labeling

- Product Codes

Marketing & Sales

- Defines product market and positioning

- Confirms consumer need for a new product through surveys and consumer data

- Develops advertising strategy

- Monitors competitor’s sales and new product introductions

- Helps design product packaging, especially tied to attracting the target audience

- Has input on the product name

Challenges of Product Development

- Just because you think it is a good idea, does not mean everyone else does.

- Sometimes things just do not work like they are supposed to (scale-up changes product characteristics, shelf life is not long enough, low consumer acceptance, etc.)

- Ingredient sourcing and costs

- Processing and equipment limitations

- Communicating with a Multidimensional Team can be difficult because each background has their own:

- Area of Expertise

- Goals and Objectives

- Ability to understand other disciplines

- Can be overlap or gaps in functions depending on company structure

Timeline for new product development

- Quick: 3-6 months

- A line extension for an already existing product

- Example: A new flavor of a popular soda

- Average: 6 months-1 year

- A new product, but still can be made on existing equipment

- Example: A new type of cereal

- Long: 1-3 years

- A brand new product – could be hard to make or new equipment may need to be designed/purchased.

- Examples: co-extruded snacks and plant-based meat alternatives

- Developing a new ingredient often takes longer than developing a finished food product because there are more regulatory and sales hurdles involved.

Recap on the Product Development Process

- Product Development is the process of creating, processing, and commercializing a new product.

- New products need to be of interest to a target market.

- The timeline can range from 3 months to 3 years.

- Product development teams are made up of members with a variety of backgrounds.

Product Development Scope

It is important to be able to ideate openly & creatively. However, ask yourself, “Does the product already exist?” and “What are our company’s new idea limitations?”. Below are common limitations for product development courses:

- Avoid mixes, line extensions, and assembly products.

- Avoid expensive ingredients or be ready to discuss how to pay for them.

- Typically a course does not have an alcohol license.

- CBD oil is not yet legal in food items in some states.

- Processing equipment availability needs to be considered for your new product idea.