13 Formulation Design – How to Set Up Experiments and Track Variables

It can be daunting to figure out where to start when taking a new product concept and making it a reality. Your team will need to be smart and use educated reasoning to maximize limited time and resources. This chapter will walk you through the process and help get you started.

Making a Food Concept into a New Food Product – Start with a Plan

- Once a new product concept is decided upon, your team will need a formulation starting point.

- Finding existing formulations and recipes and then modifying and combining them as needed is often the easiest way to start.

- Look up usage levels for ingredients, especially if specialty or industrial ingredients are needed (gums, modified starches, etc.).

- Study the existing recipes, formulations, and processing instructions and look for similarities and differences. Think through ingredient functionality and purpose of processing steps to choose the best starting place(s).

Make 2-3 Starting Formulations

- Convert volume measurements to weights and calculate percent by weight right away. Converting volume measurements to weights can be done by carefully weighing out volumetric measurements of ingredients or by looking at reputable references such as the USDA FoodData Central.

- Weights → Percents: Ingredient Weight/Total Weight = % by Weight

- For Baker’s Weight: % by weight of an ingredient/% of flour weight(s) in formula

- Converting to weights makes it easier to track variable changes.

- It also allows additional calculations, especially if targeting a specific nutrient content amount.

- Plus faculty cannot answer ingredient usage questions without the formulation percents.

- Take notes and record observations while making the formulation and evaluate the finished product in detail.

- Determine which formulation and process worked the best and why.

Decide what changes need to be made to reach the optimum gold standard food product.

- Based on the characteristics of the best iteration and the changes that need to be made, make a list of the most effective variables to test.

- There is not enough time or resources to test each variable, so it is important to think through the system and use educated reasoning to narrow down variables to test.

- Keep cost in mind. If you are using an expensive ingredient, could you use a less expensive ingredient and get almost the same functionality and product quality? It is recommended to make the smallest batch size that works on equipment and is needed for sensory evaluation.

- Once variables are chosen, start testing one variable at a time. It is important to only change one ingredient type, ingredient amount, or processing step at a time to track and understand the results of each experiment.

Adjusting and Tracking Variables

- When adding a new ingredient, research usage levels. Depending on the application, it is often most efficient to test the high usage level first. This is the best way to see and evaluate the functionality of the ingredient. Then the level can be reduced as needed.

- Addition vs. Substitution: When adjusting a formulation, it can either be done by addition or by substitution.

- Addition is taking the existing amounts of ingredients and simply adding another ingredient. This method dilutes or reduces the percentages of other ingredients. It makes the most sense if the ingredient function is different than other ingredients already in the formula.

- Substitution takes out all or part of one or more ingredients and replaces that amount with another ingredient. This keeps the amounts and percentages of the other ingredients the same, but it replaces one ingredient functionality with another ingredient functionality. Substitution makes the most sense if the new ingredient has a similar function to another ingredient already in the formula.

- It can be difficult to decide on addition versus substitution. Think through the formulation and the variable you want to test and then evaluate both options to determine which makes the most sense.

- Track the formulation and processing changes and your detailed observations and results in the lab notebook. Also, use an Excel file to track the formulations. The Excel file tracking will allow easy variable tracking and will save time calculating percentages.

A Formulation Example – Adding Fiber to Pancakes

First, review the formula and think about the function of each of the ingredients. Sometimes functions can be confusing. If this is the case, consider how the pancake would turn out without the ingredient added.

| Pancake Ingredients | Percent by Weight | Ingredient Function |

| All-purpose Flour |

30.8 |

Gluten Structure (Minimal), Starch Gelatinization |

| Baking Powder | 2.5 | Leavening |

| Sugar | 2.1 | Sweetness, Tenderizing (Minimal), Maillard Browning |

| Salt | 1.0 | Taste |

| Milk, 2% | 52.7 | Hydrate Dry Ingredients, Flavor |

| Egg | 8.5 | Hydrate Dry Ingredients, Structure, Maillard Browning |

| Oil | 2.4 | Tenderizing, Flavor (Minimal) |

|

Total |

100.0 |

Now compare addition and substitution methods of adding fiber to the formula. The goal in this scenario is to add fiber to the recipe to get an excellent source of fiber per serving: (5.6 grams / 110 gram serving). Note that for simplicity we are assuming the fiber ingredient is 100% fiber. This is not normally the case but works best here to illustrate differences.

| Option 1 – Addition (makes sense if the ingredient function is different than other ingredients already in the formula) | Option 2 – Substitution from similar ingredient(s) (makes sense if the ingredient is similar to another ingredient already in the formula) | |||

| Pancake Ingredients | Weight (in grams) | Percent by Weight | Weight (in grams) | Percent by Weight |

| All-purpose flour | 180.0 | 29.2 | 149.2 | 25.5 |

| Fiber Ingredient | 31.4 | 5.1 | 29.8 | 5.1 |

| Baking Powder | 14.4 | 2.3 | 14.4 | 2.5 |

| Sugar | 12.0 | 1.9 | 12.0 | 2.1 |

| Salt | 6.0 | 1.0 | 6.0 | 1.0 |

| Milk, 2% | 309.0 | 50.1 | 309.0 | 52.8 |

| Egg | 50.0 | 8.1 | 50.0 | 8.6 |

| Oil | 14.0 | 2.3 | 14.0 | 2.4 |

|

Total |

616.8 | 100.0 | 584.4 | 100.0 |

In this scenario, deciding between addition and substitution will likely center around the fiber ingredient characteristics. If it is a fiber ingredient like wheat bran or oat bran, the fiber ingredient will function similarly enough to flour for substitution to make the most sense. If the fiber is soluble with low viscosity like inulin or resistant maltodextrin, the fiber ingredient does not have similar functionality to the ingredients listed and addition may make more sense.

Material Balance

- Track the material in the system. This tracking will provide context for ingredient functionality and is necessary for generating the nutrition facts panel.

- Measure and record data throughout the formulation testing, NOT just once the gold standard is reached.

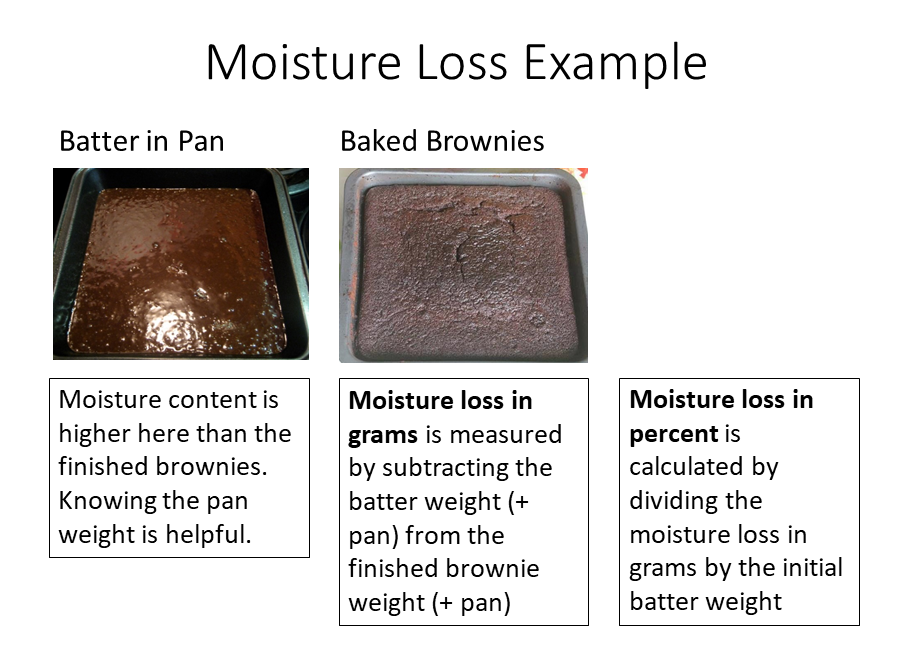

- Measurements include processing loss, moisture loss or gain, and fat loss or gain and will depend on the formulation. The most common material balance measurement is moisture loss through cooking, baking, or dehydrating. It can be as simple as measuring the weight of the product before and after the processing step to calculate water loss.

- See the brownie moisture loss example below.